Absorbers

RF/Microwave Absorbers & Dielectric Materials

See our leading line for free space, cavity resonance, and near-field applications.

Why Laird? We are equipped with the technical know-how, software, and modeling capabilities to solve complex project issues.

As a leader in the design, development, and manufacturing of RF absorber materials, we understand that while material quality and design are important, being able to adequately solve and perfect challenges that arise during the design phase is key to a successful consumer experience. Our engineers thrive on innovation and welcome any request that comes our way. This is what separates us from our competitors – expert knowledge and high-quality products developed over decades.

We have a full line of microwave absorber and mm wave absorber products for free space to cavity resonance through near field applications as well as low loss dielectric materials, such as filled polymers. Custom molded elastomeric and thermoplastic, reticulated foam, along with textile, liquids and custom composite products are on the shelf. Other key benefits include:

- Testing, measurement and verification capabilities

- Electromagnetic modeling and product design

- Pre-loaded parameters in leading modeling software

- Full custom formulation

- Frequency band from MHz to > 100 Ghz

- Integrated Multifunctional absorption solutions

Complete your project with the materials necessary for endurance and the expertise for long-term success. Take a look at our product sectors for more details and specifications. Or for a quick scan of some of our microwave absorber solutions, see this summary.

Explore Solutions

- Low Loss Dielectrics

See our full line of high-quality, high performance, low loss dielectric materials ranging from 1.05-30 dielectric constant available in various formats from rigid to flexible, compact to foam.

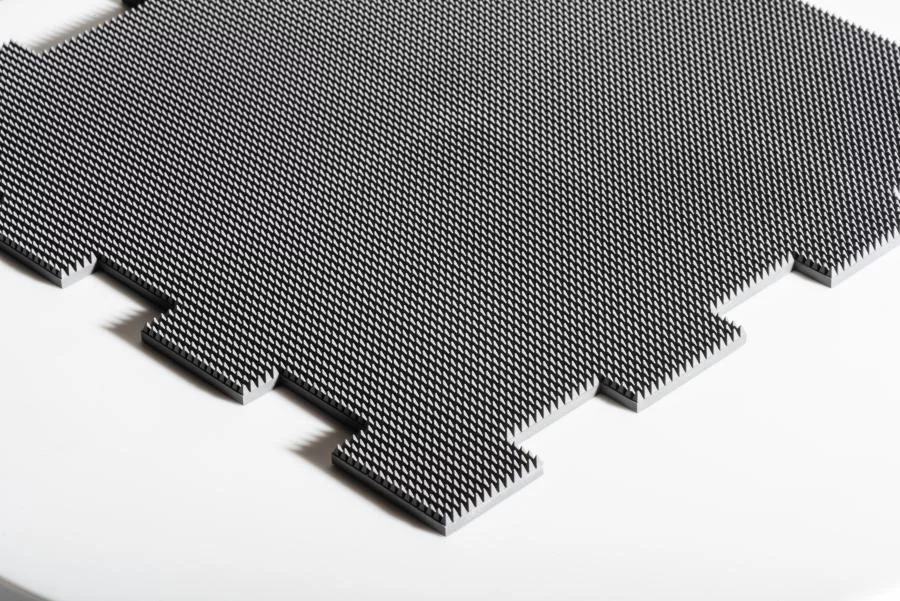

- Microwave Absorbing Foams

Low end cut-off RF absorbers of impregnated polyurethane foam. The standard solution to solve reflectivity issues.

- Microwave Absorbing Gap Fillers

Lowering EMI noise and opening a thermal path, hybrid absorbers in interface configurations resolve compliance issues at minimum deflection force.

- Elastomers and Films

Net good shielding from low to high frequencies and solve issues like internal cavity resonances up to the mm wave range. Suppress noise in the near field range.

- Military Specialty Microwave and Custom Magnetic Absorbers

Our high-performance microwave absorbers are excellent for rugged military use.

- Injection Molded, Casted and Machined

Pre-cut materials won’t work? Use our epoxy, silicone-based and thermoplastic for casting and customized molding/machining in 3D complex parts.

- Sample Kits / Accessories

Order samples of our durable bonding solutions such as absorber tapes, adhesives and patching kit accessories.